Powering

operational data

Our Expertise

Linking data and people

We specialise in value-added solutions, consultancy, and support to our customers and partners in the Power, Oil & Gas, Mining & Metals, Food & Beverage, and Chemical Refineries market sectors, both in Australia and internationally. Our experienced team are your partners in progress, helping you optimise operations and leverage IoT and analytics for predictive insights.

Operational intelligence & process automation

We excel in designing and supporting integrated operational systems, specialising in SCADA/HMI, advanced PLCs and historian solutions. We ensure secure data storage and cybersecurity to protect critical assets. Our advanced analytics tools enhance operational insights and decision-making, while our historian solutions facilitate data aggregation, trend identification, and actionable improvements.

Data integration

As specialists in data integration across the OT and IT domains, we excel in integrating with partner solutions and managing vast amounts of operational data, ensuring data consistency, contextualisation, and high-quality information for advanced analytics and business intelligence.

Consulting & advisory

Our team of seasoned consultants provides strategic advisory services, from operational strategy development and business case preparation to change management and technology roadmaps. We tailor our approach to meet the unique needs of each client, fostering long-term partnerships anchored in trust and collaboration.

Support services

We are dedicated to ensuring the sustained success of our solutions post-implementation. Our comprehensive support services include 24/7 assistance, system monitoring and proactive maintenance. Our entire team is accredited by AVEVA, ensuring that the highest standards are met. Our support services ensure that any issues are promptly addressed, minimising downtime and maximising system efficiency.

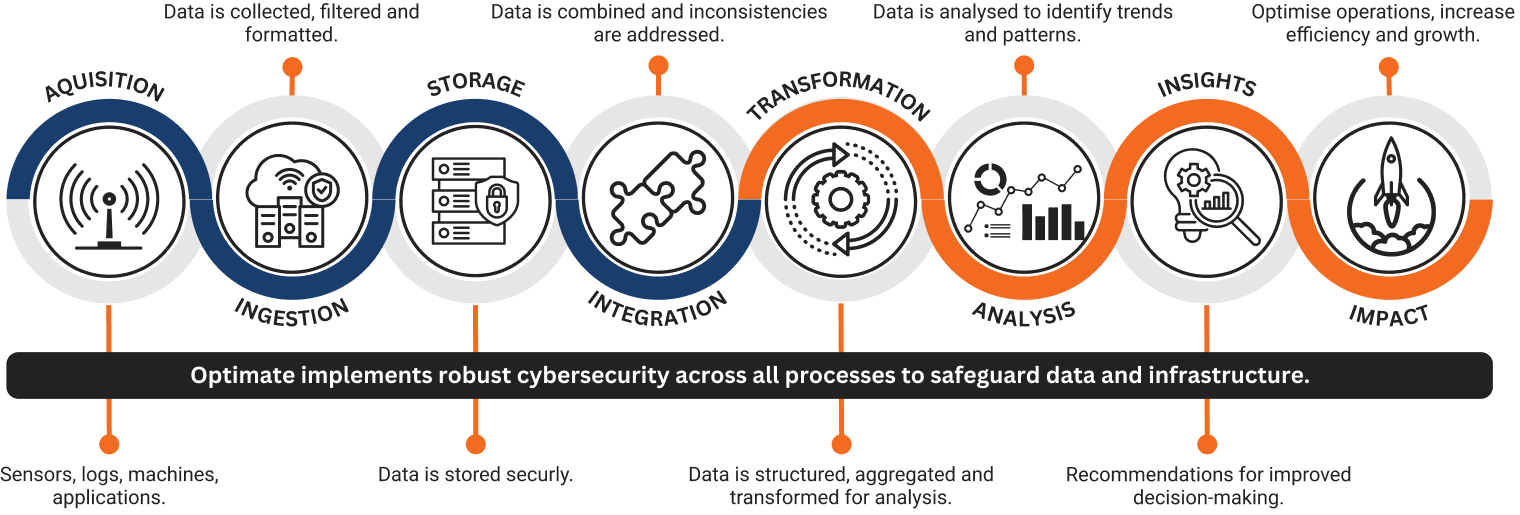

Raw data to actionable insights

The operational data value chain

Our data chain approach takes you from data acquisition to impactful business insights, turning raw data into strategic information that enhances efficiency and drives growth. Explore how our end-to-end solutions can harness transformative power of data in driving your operational success.

Why optimate

Unleash the power of data integration

We’re a team of passionate data engineers who transform raw data into actionable insights, empowering businesses to optimize performance and achieve strategic goals. We go beyond the numbers, unlocking the hidden stories within your data through advanced modeling and analytics.

Efficiency & productivity

Gain deeper insights to optimize processes, resource allocation, and strategic decision-making.

Enhanced customer insight

Understand your customers better, personalize offerings, and drive improved customer engagement.

Mitigate risk & uncertainty

Proactively identify potential issues and opportunities through predictive analytics.

A competitive advantage

Leverage data-driven strategies to gain an edge in your industry.

With purpose

Our commitment

Optimate leads the way in unlocking the transformative power of operational data by helping businesses integrate data from diverse sources and convert it into valuable insights.

— Mark Darlington, Optimate CEO

Your partner

Data integration & consultancy specialists

Our mission is to unlock the true potential of operational data, leveraging technology and expertise to drive innovation and provide actionable insights. As a trusted partner for organizations across diverse industries, both in Australia and around the world, we have consistently delivered award-winning solutions that transform data into a strategic asset.

Have you made the switch from PI ProcessBook to Vision?

PI ProcessBook reached EOL in December 2024.

Trusted by the best

Client success

Expertise that delivers

Don’t take our word for it — our proven track record speaks for itself.

-

25+ years in industry

-

Certified engineers

-

Diverse skillsets

Alinta Energy

“The significant improvements we have made and continue to make, in our operational data would not have been possible without Optimate’s collaborative approach to solution design. We have appreciated Optimate’s ability to quickly understand our requirements, as well as their flexibility through the delivery stages which kept our program on track despite a diverse set of resourcing and technological challenges across our generation assets.”

— Buzby Kuramoto, General Manager, Merchant Energy Operations

Key impacts

- Delivered PI System upgrades, PI-AF Development, Dispatch & Trading Visualisation Displays.

- Central PI archive available to every Alinta employee, at any time from any location.

- Optimates IT support and system monitoring reduced unplanned downtime of the PI ecosystem to nearly 0% over the course of 9 months.

Origin

“We chose to work with Optimate as they understood our requirements and were willing to work cohesively with our team. Optimate proved to be flexible and agile during the feasibility, design and implementation of the MSC Project, giving them the edge over competitors. Their expertise in Solution Architecture and Systems Integration ensured that our Generation sites were brought together into a functional fleet management system for our operations.”

— Jim Cooley, Asset Intelligence & Information Manager

Key impacts

- Design and integration of the Monitoring and Support Centre (MSC) systems for high availability, real time, consistent access to all data, across 9 sites, with their generation portfolio.

- Significant reduction in time to respond to production critical events.

- Centralised operations streamlined workforce and reduced errors.

- Centre of excellence for operational improvement of generation assets.

Large Australian Mining Co.

We partnered with a leading Australian mining company to enhance operational efficiency and safety. Our comprehensive approach focused on minimizing operational wastes, emissions, and discharges while ensuring accurate production allocation. We also optimized the performance of Safety Instrumented Functions (SIF) and improved safety system shutdown activations, resulting in a more resilient and environmentally responsible operation.

Key impacts

- Operations Wastes, Emissions and Discharges

- Production Allocation

- Safety Instrumented Function (SIF) Performance

- Safety System Shutdown Activations

Major Australian Energy Co.

We worked with a major Australian energy company to develop new PI AF databases. These databases provided a robust and reliable way to extract necessary data for reporting and business operations, including building complex calculations needed to feed business logic using the PI Analysis component. The solution was built to be resilient to the data latency and data quality problems that are common with diverse and disparate systems from many different plants.

Key impacts

- Created AF databases for reliable data extraction.

- Implemented complex calculations using PI Analysis.

- Ensured resilience to data latency and quality issues.

- Integrated diverse systems from multiple plants.

New Zealand Electric Power Transmission Co.

To streamline data management and ensure centralized accessibility, we implemented PI to PI replication to transfer data from four remote site PI Data Archive servers to a centralized corporate PI Data Archive. Additionally, we utilized PI Auto Point Sync to automatically create new PI Points from upstream systems in the corporate data system. This process involved the management of approximately 500,000 PI Tags.

Key impacts

- Implemented PI to PI replication for data transfer.

- Centralized data from four remote site PI Data Archive servers.

- Used PI Auto Point Sync for automatic PI Point creation.

- Integrated new PI Points from upstream systems.

- Managed approximately 500,000 PI Tags.